Pipe bending and forming center

Full production cycle

Дивитись сертифікат

Дивитись сертифікат

Центр гнуття та формовки труб в Україні «Rud E.S.»

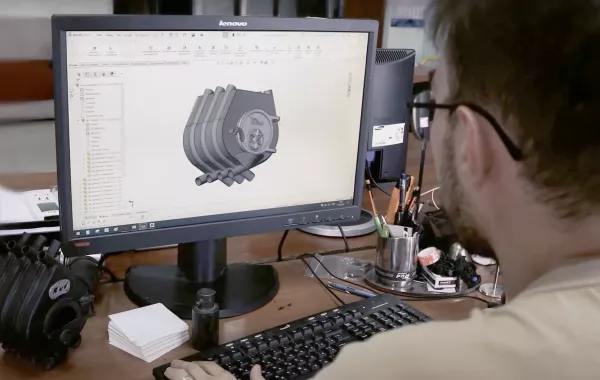

Виробництво від проєкту до готового виробу

Якість. Надійність. Досвід.

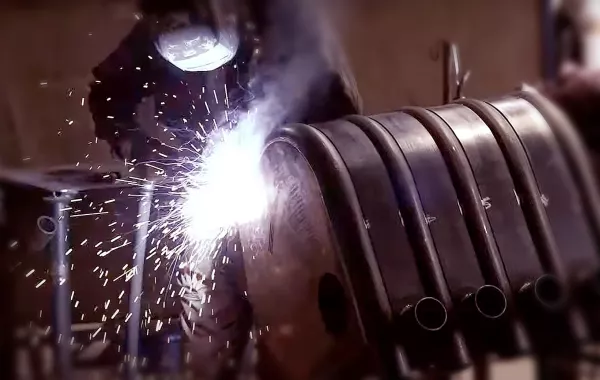

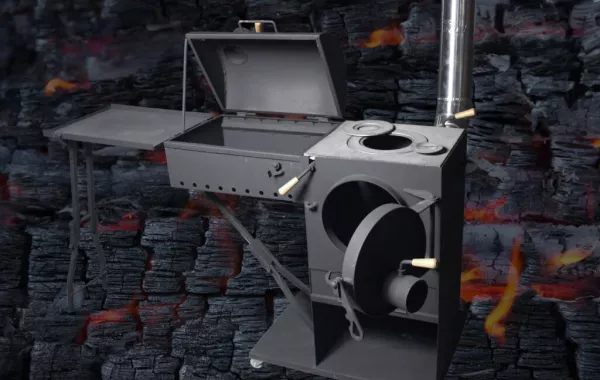

Наша компанія «Rud E.S.» є підприємством повного циклу: від проєктування до готового виробу. Компанія має багаторічний досвід, сучасне виробниче обладнання та професійну команду. Тому ми якісно та вчасно реаліуємо проєкти будь-якої складності, починаючи від ідеї і закінчуючи серійним виробництвом. Ми є надійним партнером у сфері виготовлення та обробки металевих виробів.

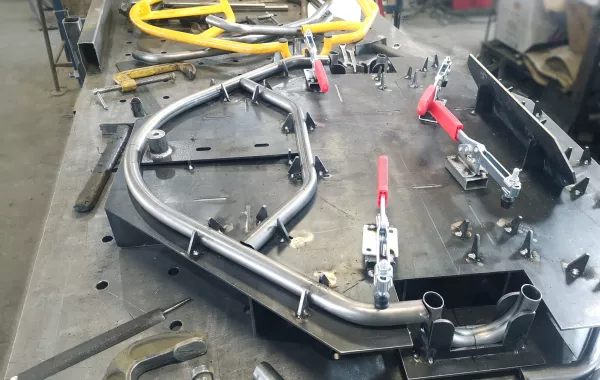

Послуги з гнуття труб та комплексні замовлення металообробки — від проєкту до готового виробу

Послуги, які ми пропонуємо

Дивитись сертифікат

Дивитись сертифікат

Підприємство має сертифікат Системи менеджменту відповідно до EN ISO 9001:2015

Руд є спеціалізованим підприємством з більше ніж 10 річним досвідом гнуття труб. Нове обладнання, технічно грамотні спеціалісти, великий досвід — запорука якості та надійності як партнера.

Руд виконує завдання комплексно, даючи технічну підтримку замовнику на всіх етапах виробництва та проєктування.

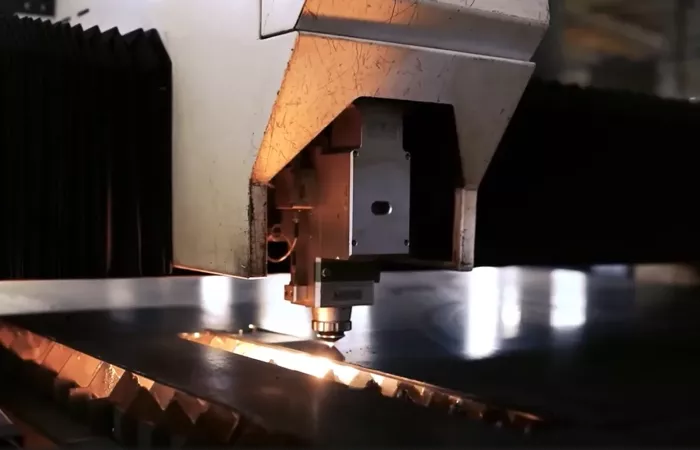

Потужна технічна база

та контроль всіх етапів роботи виробів

Руд є виробником та розробником верстатів для редукування труб. Власна розробка, технічна підтримка, запчастини та інше в наявності. Ми проєктуємо верстати та оснащення під конкретне завдання.

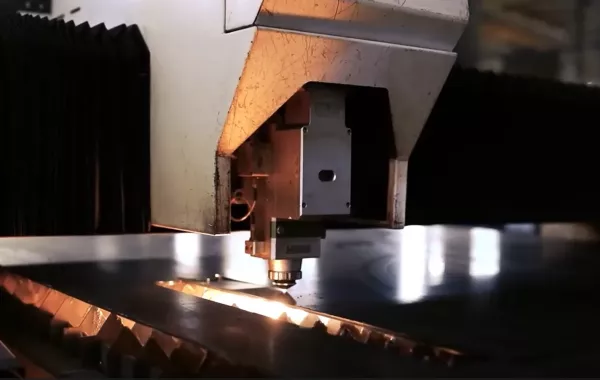

Руд підриємство яке має на балансі велику кількість обладнання, яке в змозі виконати комплексні проєкти. Листозгинальний верстат з ЧПК, гідравлічні преси 160 та 315 тонн, фрезерні оброблювальні центри з ЧПК, точковий зварювальний верстат та інше. (73 одиниці + робот)

Руд є першою в Україні компанією, яка спеціалізується на обробці труб. Ми пропонуємо не тільки послуги, але й технології, технічну підтримку, обладнання, навчання та свій досвід.

Підприємство знаходиться в самому центрі України в місті Дніпро.

Виробничі потужності і заводоуправління знаходяться на території більше ніж 3000 кв.м. Цех оснащений сучасним парком обладнання, в більшій масі з ЧПУ, що дозволяє виробляти продукцію з високими вимогами щодо якості в короткі терміни за доступною ціною.

Високий професіоналізм і сучасний підхід інженерів і конструкторів, дозволяє створювати якісну і високотехнологічну продукцію визнану не тільки в Україні, але і в світі, що підтверджено європейськими та місцевими сертифікатами країн імпортерів.

За 15 років плідної роботи ми розвинули і продовжуємо розвивати ряд перспективних напрямків як в продуктовому (товари і послуги) сегменті так і в технологічному.